焊接闸阀

焊接闸阀 阀门首页 > 产品展示 > 闸阀 > 焊接闸阀 >

阀门首页 > 产品展示 > 闸阀 > 焊接闸阀 >

产品名称:太阳集团appZ961H-25 DN200(生产设备厂家)[ 2023-12-29 ]

- 订购热线:021-64162222

- 订购传真:021-62677999

- 质量稳定:实行全过程质量监控,细致入微全方位检测!

- 价格合理:高效内部成本控制,减少了开支,让利于客户

- 交货快捷:先进生产流水线,充足的备货,缩短了交货期!

- 产品介绍

- 规格尺寸

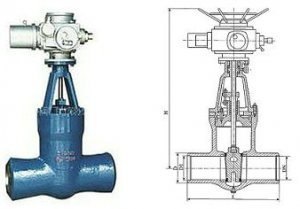

- 结构图片

一、太阳集团appZ961H-25 DN200(生产设备厂家)介绍

太阳集团网址首页官网电动焊接闸阀(Z961Y电站闸阀)由焊接式闸阀配备电动执行机构组合而成,支管两端为焊接的结构,中部采用无阀盖压力自紧式,通过电动装置电源驱动使阀杆做升降运动,从控制闸阀的启闭。电动焊接闸阀主要用于水、蒸汽、油品、过热蒸汽管道等高温高压场合使用,压力一般在PN25.0MPa以内。具有耐磨、耐高温、抗腐蚀等优点,既能就地操作,也可以进行远距离控制。适用于ANSI CLass1500-3500,工作温度在-29~570℃的石油、化工、火力电站等各种工况的管路上,切断或接通介质。

二、太阳集团appZ961H-25 DN200(生产设备厂家)优点

1、壳体精密铸造工艺,外观光洁,组织均匀,满足高中低压要求。

2、焊接太阳集团app设计制造按JB/T3595等标准,可与国产设备配套使用。

3、阀门中腔采用压力自紧式密封结构、密封性能好,支管两端为焊接结构。

4、阀杆经调质和表面氮化处理,有良好的抗腐蚀性和抗擦伤性。

5、高压水强度,高压气体强度,无损检测等多道检测,全面控制铸钢件质量。

三、太阳集团appZ961H-25 DN200(生产设备厂家)性能规范

型号

公称压力

(MPa)实验压力

工作温度(℃)

适用介质

强度水(MPa)

密封(水)空气(MPa)

低压密封空气(MPa)

Z961H-16C

Z961W-16P(R)1.6

2.4

1.8

0.6

≤425

硝酸类

Z961W-25P(R)

2.5

3.8

2.8

0.6

≤200

醋酸类

Z961W-40P(R)

4.0

6.0

4.4

0.6

≤200

硝酸类

Z961W-64P(R)

6.4

9.6

7.0

0.6

≤200

醋酸类

四、太阳集团appZ961H-25 DN200(生产设备厂家)主要零件材质

阀体/阀盖

ZGICr18Ni9Ti

ZG00Cr18Ni10

ZG1Cr18Ni12M02Ti

ZG00Cr17Ni14M02

WCB

零件名称

ZGICr18Ni9Tit系列

ZG00Cr18Ni10系列

ZG1Cr18Ni12M02Ti系列

ZG00Cr17Ni14M02系列

WCB系列

闸板

ZGICr18Ni9Ti

ZG00Cr18Ni10

ZG1Cr18Ni12M02Ti

ZG00Cr17Ni14M02

1Cr13

阀杆

1Cr18Ni9Ti

00Cr18Ni10

1Cr18Ni12M02Ti

00Cr17Ni14M02

1Cr13

填料

PTFE编织

PTFE编织

PTFE编织

PTFE编织

石墨

垫片

304L+PTFE

304L+PTFE

316+PTFE

316L+PTFE

石墨

压盖

ZGICr18Ni9Ti

ZG00Cr18Ni10

ZG1Cr18Ni12M02Ti

ZG00Cr17Ni14M02系列

WCB

填料压环

1Cr18Ni9Ti

00Cr18Ni10

1Cr18Ni12M02Ti

00Cr17Ni14M02

1Cr13

螺栓

1Cr17Ni2

1Cr17Ni2

1Cr17Ni2

1Cr17Ni2

35CrMoA

螺母

1Cr18Ni9Ti

1Cr18Ni9Ti

1Cr18Ni9Ti

1Cr18Ni9Ti

45

公称通径DN/mmN0minaldiamecer

公称压力PN/MPaN0minalpressure

主要外形尺寸和连接尺寸/mmMain external andc0nnecting dimensi0ns

重量/kgWeight

L

H

D

D0

∝

W

50

2.5

250

345

64

49

37030’

250

24

65

270

395

82

66

37030’

250

36

80

280

425

95

78

37030’

300

52

100

300

510

117

100

37030’

300

67

125

325

570

144

125

37030’

350

95

150

350

725

172

151

37030’

350

135

200

400

820

223

201

37030’

400

210

250

450

890

278

253

37030’

450

300

300

500

1070

330

303

37030’

550

395

350

550

1320

382

351

37030’

650

530

400

600

1450

432

398

37030’

750

685

450

650

1560

484

450

37030’

750

906

500

700

1720

535

498

37030’

850

1130

600

809

1880

638

600

37030’

900

1387

700

900

2083

738

700

37030’

950

1894

800

1000

2590

840

800

37030’

1000

2621

50

4.0

250

345

64

48

37030’

300

30

65

270

395

82

66

37030’

300

42

80

280

425

95

78

37030’

350

57

100

300

510

117

100

37030’

350

75

125

325

570

144

125

37030’

400

105

150

350

725

172

151

37030’

400

150

200

400

820

223

199

37030’

450

232

250

450

890

278

251

37030’

550

330

300

500

1070

330

301

37030’

650

430

350

550

1320

382

349

37030’

750

570

400

600

1450

432

396

37030’

850

730

50

6.4

250

350

64

48

37030’

300

34

65

280

405

82

65

37030’

300

48

80

310

435

95

76

37030’

350

65

100

350

515

117

98

37030’

400

81

125

400

580

150

128

37030’

400

112

150

450

735

172

149

37030’

450

161

200

550

835

223

197

37030’

550

255

250

650

905

278

245

37030’

650

390

300

750

1080

330

293

37030’

750

515

350

850

1340

382

341

37030’

800

695

400

950

1460

432

386

37030’

900

885

50

10.0

250

350

64

48

37030’

300

37

65

280

405

82

63

37030’

300

52

80

310

435

95

74

37030’

350

70

100

350

515

117

97

37030’

400

86

125

400

580

150

124

37030’

400

118

150

450

735

172

144

37030’

450

168

200

550

835

223

189

37030’

550

263

250

650

905

278

235

37030’

650

405

300

750

1080

330

281

37030’

750

536

350

850

1340

382

333

37030’

850

732

400

950

1460

432

376

37030’

950

947

上一篇:Z961Y-100I DN400电动焊接高温高压闸阀 / 下一篇:Z962Y p54 100v电动电站高温高压焊接闸阀

阀门资讯

阀门资讯 手动dn800闸阀厂家,dn800手动闸阀厂家

手动dn800闸阀厂家,dn800手动闸阀厂家

沪公网安备 31011402005796号

沪公网安备 31011402005796号

走进湖泉

走进湖泉